Josh Frick, Interdisciplinary Sculpture, 2022

Josh Frick is a senior in the Interdisciplinary Sculpture program who concentrates his studio practice in digital fabrication. He pushes machines to their limits, redefines their utility, and uses coding to ask questions about the nature of patterns and randomness in our universe.

Project Overview

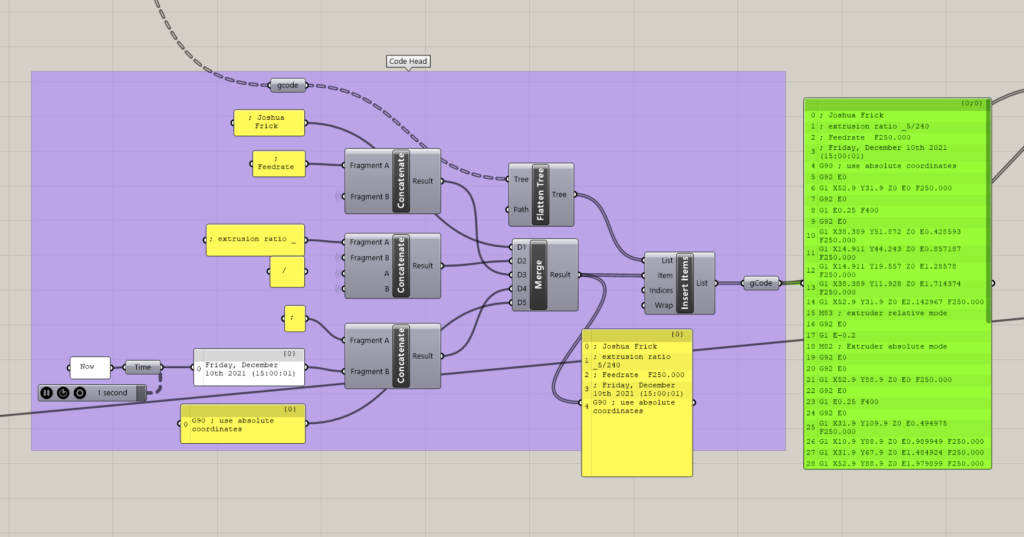

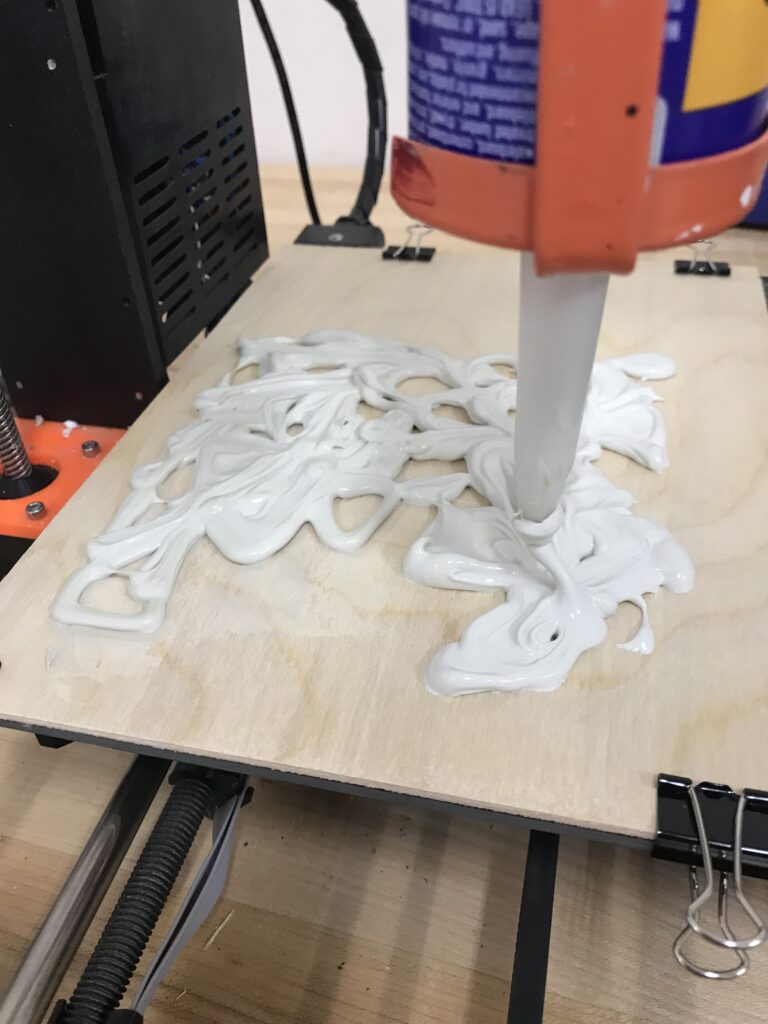

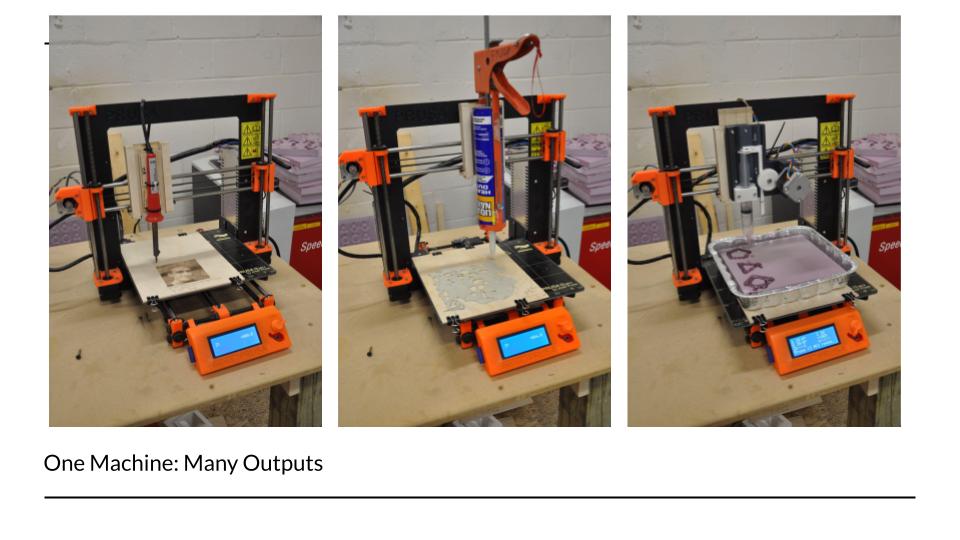

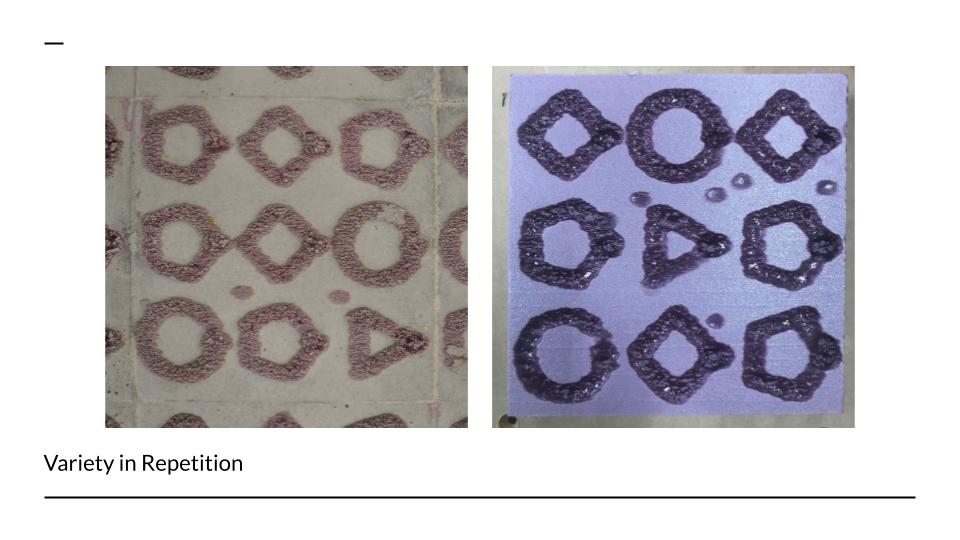

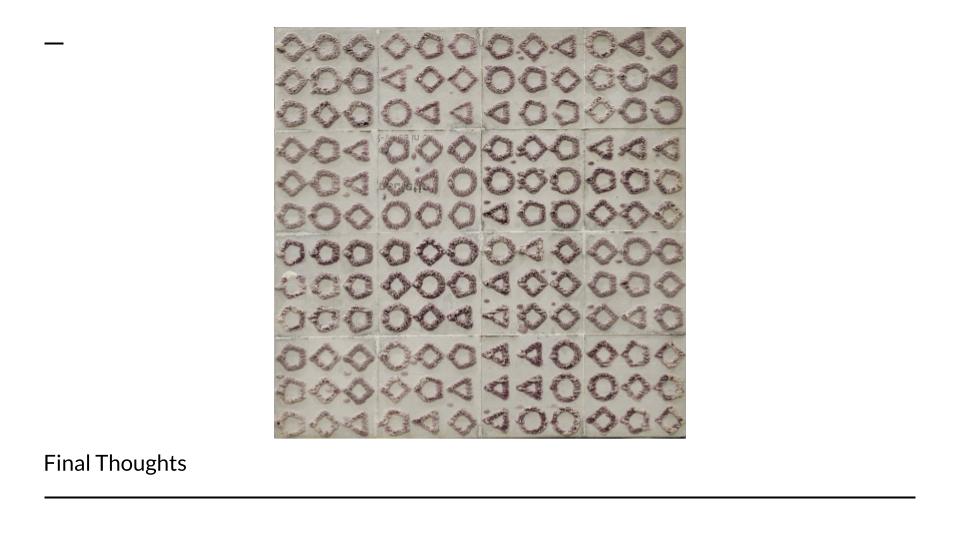

In Irregular Manufacturing, Josh Frick explores the power dynamic between machine and its designer. This project uses a modified 3D printer and algorithms written in grasshopper to investigate how purpose-built, imprecise machines can turn a singular input into a varied output through repetition to highlight the material intelligence and influence of the machine. Designed to make mistakes and to change each time the code is run, Irregular Manufacturing creates a collaborative relationship between designer and machine, where the designer is ultimately in control but relinquishes part of the final form to the choices of the machine.

Load your project overview images in the gallery below. The exact number of images is flexible, but 3-6 images is usually good for this.

Then do a little sidebar action:

In the right hand sidebar, click the “Document” tab to bring up setting for this post. Confirm that the “Categories” are set to “Projects” and “UNRVL_19” only. Add a few keywords specific to your project in the “tags” section. Set the “Featured Image” for this post; this will be what represents your project in the aggregate lists of projects on the site. It will also be the image in the banner of this post. It one of your “project overview” images, if you like. Set the “excerpt” for this post by pasting in your 50 word project overview. This is the text that will appear in aggregate lists of project on the site. Lastly, confirm the the layout is set to “Custom” and “One Column: Wide.”

Process

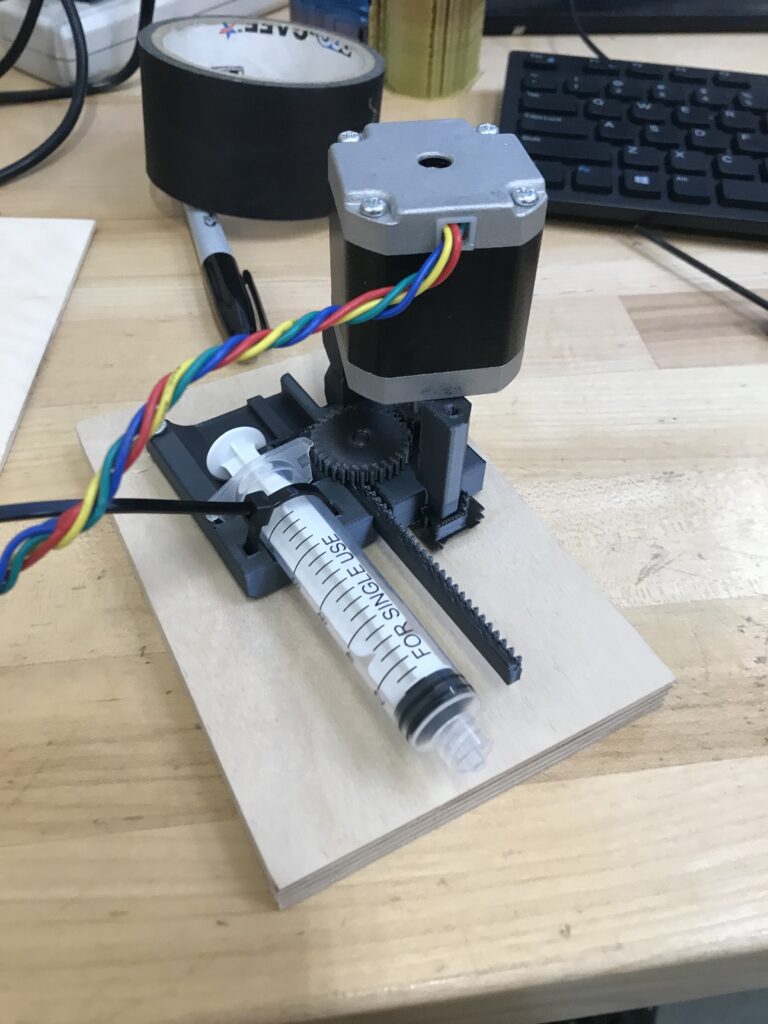

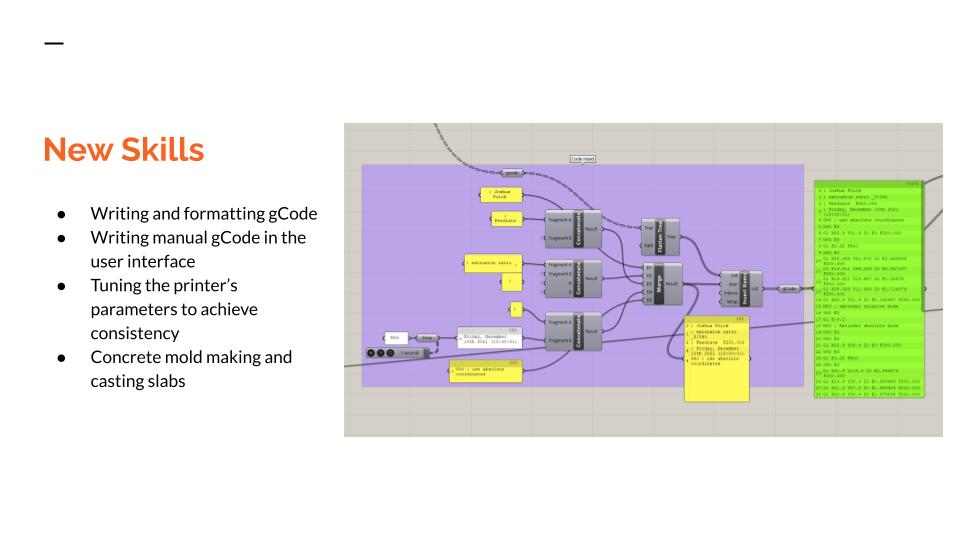

Irregular Manufacturing is built on the 3-axis motion of a retired 3d printer. Through code written in Grasshopper 3d and modifications of the machine, the printer was given three new outputs: a wood burning tool, a caulk gun, and a syringe pump. Each output was tuned to give the machine accuracy and repeatability without entirely removing variation due to environmental factors and the natural tendencies of the material. The syringe pump was used with acetone, which dissolves foam, to draw the patterns of the shapes eternally cast into the concrete cube.

Presentation

- Title slide

- Research Question

- Process

- Skills learned

- Results

- Conclusions

- Acknowledgements

Learn More

Creative Process Journal

Personal Website

Instagram

Email: Joshuazfrick@gmail.com